How the Spiro Conveyor Floor works

The principle of operation of the Spiro floor is the difference in friction between the floor and the cargo. In a lorry trailer, for example, the floor consists of 24 aluminium profile sections which can move lengthwise. These profile sections are split into three groups of 8 which are driven independently by separate hydraulic cylinders.

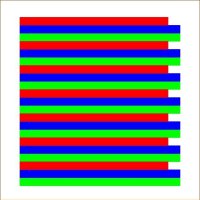

The floor transports material by repeating a movement sequence with the hydraulic cylinders. The diagrams below explain the sequence:

Moving Floor Sequence

Stage 1: The first group of aluminium floor sections moves back 150mm quickly.

The cargo stays were it is.

Stage 2: The second group of aluminium floor sections moves back 150mm quickly.

The cargo does not move.

Stage 3: The third group of aluminium floor sections moves back 150mm quickly.

The cargo remains stationary.

Stage 4: All three groups now move forward 150mm simultaneously. The cargo is now advanced 150mm.

The process now repeats itself

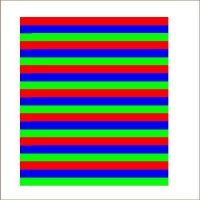

Animation sequence

Spiro have enhanced the original concept by the introduction of electronic control of the hydraulic actuators. This gives a much smoother movement and avoids a lorry digging into the ground when it is operated on a soft surface.

Spiro have enhanced the original concept by the introduction of electronic control of the hydraulic actuators. This gives a much smoother movement and avoids a lorry digging into the ground when it is operated on a soft surface.

When used in static applications such as MRFs and Compost facilities, the principle is exactly the same. However, floor widths can be increased by adding more bars. They can be extended to 50 metres length.