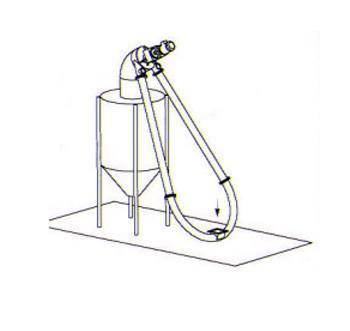

Schrage Conveyor Application 3 - Raw Material Elevator

Why use a Schrage Tube Chain Conveyor

Bucket elevators or pneumatic conveyors are sometimes used to lift bulk material from one level to another. But there are inherent problems with these solutions, especially with respect to fugitive dust in the bucket type solutions and restricted run routes and high energy costs with pneumatics.

The Schrage tube chain conveyor used as an elevator prevents dust being released from the elevator and also avoids the common spillage problems which are often seen with bucket elevators. It offers significant energy savings when compared with pneumatic conveyors can provide.

The chain is self-tensioning which minimises strain on the motor, and removes the need for a tensioning station.

Ideal conveying solution

There are several applications in the UK that use this type of configuration. It is ideal for elevating raw materials ready for processing.

Typical heights of this application are circa 5m, although the conveyor could be used to elevate to 40m! The other advantage of this arrangement is that it allows a big bag or IBC to be discharged at ground level, alongside the process hopper or receiving point. Thus eliminating the need for bag lifting equipment.

The gentle handling of the tube chain conveyor also prevents attrition and separation of the material mix, ensuring that the material discharges into the hopper with the same properties it started with.

Contact us now and increase your energy efficiency!