Schrage Conveyors - Dust Collection & Discharge

Dust Handling and Management

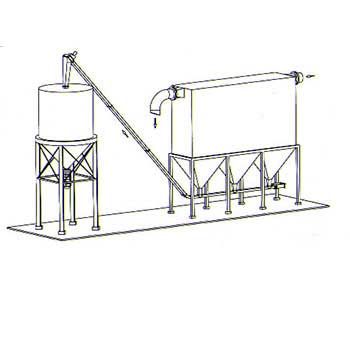

Another useful application for the tube chain conveyor is the handling of dust from filter units and discharge into storage silos.

Dust from filter units has traditionally been discharged using rotary valves feeding either a screw conveyor or pneumatic conveyors. These are costly to run, and multiple systems are needed. Renby solve these common operational problems with a single dust tight conveyor.

A common source of problems on both of these alternatives is the rotary valves. If a product is abrasive, the vanes of the valve wear quickly and need frequent replacement.

The tube chain conveyor solves this.

Due to the fact that it is a disk in tube design, the conveyor has an inherent seal over approximately 2m length. Therefore each inlet can operate at different pressures and still feed into the conveyor directly.

The tube chain conveyor can replace either situation with a single conveyor giving considerable gains in plant reliability. Furthermore, as the power consumption is relatively small (see the Technical Specification) energy efficiency increases.

So here is yet another example of how Renby limited are helping to keep the dust down in industry.

Contact Renby Ltd now and start saving money!