Schrage Tube Chain Conveyor Applications

The versatility of the tube chain conveyor enables it to be applied in a broad range of applications. These examples will give some insight.

The case studies illustrate how real problems have been solved in the UK.

This system offers "a whole new way of thinking" for conveying.Browse through the examples and then step over the boundaries that normally restrict conveyor runs to a single plane.

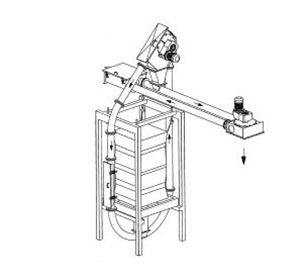

Big Bag Emptying.

Big Bags and IBC’s are in common use for bulk materials distribution and handling. Often the bags are moved around at ground level, but sometimes the material needs to be moved to a higher level.

As bulk materials handling experts, Renby found that the Tube Chain Conveyor is the best way to do this efficiently and without spills.

The chain is self -tensioning under gravity and so does not need an additional tensioning station as would be needed with alternative elevator technologies. More…

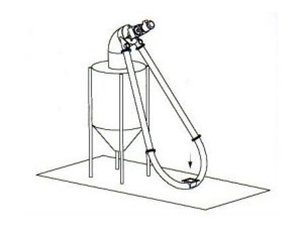

Dust Collector Discharge.

Dust from filter units has traditionally been discharged using several rotary valves combined with either screw conveyors or pneumatic conveyors. These are costly to run, and multiple systems are needed. Renby solve these common operational problems with just one dust tight conveyor. More…

Elevating Raw Materials.

Many processes need to lift bulk material from one level to another. A typical solution is to use either bucket elevators or pneumatic conveyors.

Using the tube chain conveyor as an elevator prevents the dust spillage problems which are often seen with bucket elevators and offers more versatile runs than pneumatic conveyors can provide.

As noted earlier, the chain is self-tensioning which puts less strain on the motor, and removes the need for a tensioning station. More…