What is industrial humidification?

The humidity level in a building depends upon external ambient conditions, ventilation and the temperature inside. For instance, in winter, outdoor relative humidity (RH) may be 80%, but the temperature may only be 5°C. When this air is warmed up inside the building to, for instance 20°C, then the RH will decrease to 30%. This is too dry for many processes. Therefore, humidity control becomes a necessity for a whole range of industries.

An effective industrial humidifier will increase the level of relative humidity in a room without causing wet areas to form. It also needs to be able to respond and adapt to changing local conditions. Renby’s MicronFog™ is a state-of-the-art industrial humidification system that does just that, offering maximum flexibility and simple humidification control.

How do industrial humidifiers work?

Effective humidification requires small droplets of water that can flash evaporate into the air. A traditional way to achieve this has been to use steam based systems to provide the moisture. Such a technique is expensive to run, requiring large amounts of energy to create the steam. A more effective way is to use fog to generate the humidity. The MicronFog™ system uses high pressure water and specially designed nozzles to emit billions of water droplets into the air. The majority of droplets range in size from 7 microns to 20 microns. These are an ideal size to flash evaporate, thereby humidifying the air.

Effective humidification requires small droplets of water that can flash evaporate into the air. A traditional way to achieve this has been to use steam based systems to provide the moisture. Such a technique is expensive to run, requiring large amounts of energy to create the steam. A more effective way is to use fog to generate the humidity. The MicronFog™ system uses high pressure water and specially designed nozzles to emit billions of water droplets into the air. The majority of droplets range in size from 7 microns to 20 microns. These are an ideal size to flash evaporate, thereby humidifying the air.

The MicronFog™ system is both modular and has adaptive control, meaning you can easily change the quantity and direction of nozzles for optimum humidification. The misting system increases the humidity level in the air by evenly distributing small droplets of water across the room in a fine mist. The droplets themselves are so small that they flash evaporate before they reach the floor meaning wet areas or excessive water build up is not found.

A network of humidity sensors continuously analyse the moisture content in the air and send the data back to the system. If the moisture content is too low, the system will release more fog until the desired level of humidity is achieved. Conversely, if the reading indicates the moisture content is too high, the system will pause until humidification is needed again.

Zone control enables different RH levels to be set for different areas / rooms of the building. This can reflect different requirements in parts of a process or to compensate for the location of doorways or other airflows.

Zone control enables different RH levels to be set for different areas / rooms of the building. This can reflect different requirements in parts of a process or to compensate for the location of doorways or other airflows.

Alternatively, in HVAC systems, the degree of humidification required varies with the seasons. In summer the air may already be at the right temperature and just below the required humidity, whereas in winter, large amounts of humidity will be required once the air has been heated.

Using zone control, the MicronFog™ system, a humidity injection turndown of 1:16 can be achieved with ease.

Atmospheric humidity does not remain constant throughout the day. Therefore, the system also has the facility to run different humidity levels for different times of day. This can be important for crop growers looking to maximise the growing cycle of their crop. Certain crops also thrive at different humidity levels depending where they are in their life cycle. The ability to vary humidity settings easily gives further ways to increase profitability by maximising cropping.

Atmospheric humidity does not remain constant throughout the day. Therefore, the system also has the facility to run different humidity levels for different times of day. This can be important for crop growers looking to maximise the growing cycle of their crop. Certain crops also thrive at different humidity levels depending where they are in their life cycle. The ability to vary humidity settings easily gives further ways to increase profitability by maximising cropping.

Why do you need an industrial humidifier?

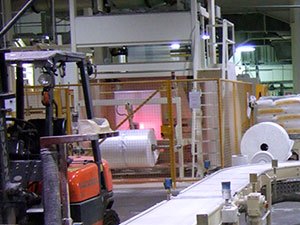

Maintaining consistent humidity levels is a challenge many industries face. Including:

- Food industry

- Agribusiness

- Laboratories

- Paper Industry

- Woodworking and lumber.

Failure to control humidification in these industries can lead to many problems and increased costs. These range from negatively impacting product quality to serious safety issues for employees working in that environment.

Failure to control humidification in these industries can lead to many problems and increased costs. These range from negatively impacting product quality to serious safety issues for employees working in that environment.

This flexibility allows you to tailor your MicronFog™ system to meet your needs. In these cases, by improving your industrial humidification control, you can improve your overall product quality and optimise your product yield. With MicronFog™ systems, controlling air moisture is simple and can save your business time and money, whilst improving yields and profitability.

Case study – Zoo

Recently a zoo approached us to look at the humidity of a visitors gallery that was intended to give the sensation of a tropical rainforest. The existing installation was quite dry and the plants were stressed. A MicronFog™ system was recommended with three zones to control humidity by the entrance, in the middle and by the exit sections. This was deemed necessary as there was no control over the frequency of opening and closing the access doors. The system was set to control the relative humidity to 65% during the daytime. One year on and the gallery is now verdant with bromeliads flowering and other plants with high moisture demands are thriving.

Recently a zoo approached us to look at the humidity of a visitors gallery that was intended to give the sensation of a tropical rainforest. The existing installation was quite dry and the plants were stressed. A MicronFog™ system was recommended with three zones to control humidity by the entrance, in the middle and by the exit sections. This was deemed necessary as there was no control over the frequency of opening and closing the access doors. The system was set to control the relative humidity to 65% during the daytime. One year on and the gallery is now verdant with bromeliads flowering and other plants with high moisture demands are thriving.

The MicronFog™ system can be placed almost anywhere and easily expanded as your business grows.

At Renby we want to save you money and help you grow as a business. We know that when we do our best work it allows you to focus on what you do best. If you’re interested in installing a MicronFog™ system, want to learn more about industrial humidifiers or require any more information then contact us today.