Increase plant safety

Reduce Dust/Spills for a Safer Working Environment

Renby help organisations to improve safety standards for dust and spills. There was a time when working in a dusty environment was just “a normal part of the job” or an “occupational hazard”. Airborne dust is now known to cause serious respiratory illnesses such as COPD and Silicosis.

You can download a free copy of the HSE guidance on Control of exposure to silica dust here. All our customers consider safety as a primary concern. Businesses must demonstrate that they are meeting and endeavouring to exceed legislation and regulatory standards.

Interruptions and litigation due to accidents or illness creates stress and wastes time and money. For temporary workers, illness and injuries can even more severely affect livelihoods. Businesses need to find effective tools to help avoid spills and suppress dust.

How do we improve safety?

Renby’s range of fogging equipment, conveyors, dosing and materials reception products are designed to help our customers to increase safety in the workplace. Our systems are often purchased following audits which highlight safety concerns about dust, explosive materials or unsafe bulk material handling practices. Renby are your experts in solving these safety concerns.

Renby MicronFog™ supresses & controls dust effectively

Compared with dust collectors or extraction systems, fog is a fraction of the cost to own and just as effective (sometimes more effective).

In health and safety audits, manufacturers and processors with MicronFogTM installations have been praised for reducing dust levels quickly and effectively. The fog is very fine and does not wet the process area, thus preventing further safety concerns.

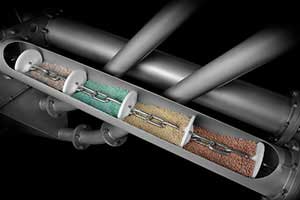

Schrage Tube Chain Conveyors.

By fully containing dust, and preventing spills, the production atmosphere is kept clean and thus safe They can also be rated to a full ATEX 20 rating to operate safely with explosive dusts.

The Schrage tube chain conveyor is a totally contained unit that ensures all material is conveyed from the inlet to the outlet with no spillage and so is equally useful for wet or sticky bulk materials.

Spirofloor® and Hydratech Toploaders

Help to ensure a safe working area. Traditional materials reception halls can be very dangerous places.

Often, several front-loaders and other vehicles are operating, increasing the risk of serious injury, or death.

The automatic moving floors automate the movement of large volumes of material so that personnel can be eliminated from the reception hall and work remotely in a safe control room.

More on materials reception with Toploaders and Moving Floors...