Tubular Drag Conveyor

What is a Tubular Drag Chain Conveyor?

Tubular conveyors of one kind or another are commonly used where bulk materials need to be transported under cover from one part of a process to the next.

A tubular drag chain conveyor is needed when materials need to be conveyed around obstacles in your facility, either around bends or in different planes (Horizontal, vertical and diagonal) without the risk of spilling material, or particle degradation.

The tubular nature of the conveyor means that product will not be affected by anything in the surrounding atmosphere. The round shape minimises damage and friction issues.

How Do Tubular Drag Chain Conveyors Work?

Also known as tube chain conveyors, tubular drag conveyors, tubular drag link conveyors and chain-disk conveyors, these conveyors use a chain and disc assembly (See above photo) to pull or “drag” material along a sealed tube in the spaces between the discs.

A drive sprocket powered by a shaft mounted motor (See right) meshes with the chain and disk assembly at the head end of the conveyor line. The chain is in a continuous loop.

A tension station at the rear of the conveyor containing a rotating idler or sprocket and a chain tensioner facilitates the chain return and tension.

How can we avoid cross contamination between batches?

Where required, a brush cleaning station can clean material off the discs at the discharge point. This ensures that particles of friable material from the last batch are not left in the conveyor and will not contaminate further batches of material.

This is particularly useful in food manufacturing or chemicals, where batches must be kept separate, or where product is easily degradable.

Where are they used?

Tubular drag chain conveyors are used in facilities handling powders, granulates, pre-mixed products, wastes, wet bulk solids, sticky materials or abrasive chemicals, minerals and hot materials such as ash. Explosion resistant and ATEX versions are also available. Quite often, they have been found capable of handling materials other systems can’t manage and have been the only solution possible.

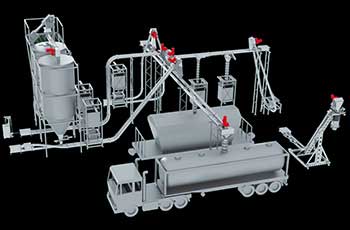

They are highly versatile in terms of design and can convey around bends, in any plane, underfloor, in tight spaces or at height - as demonstrated here.

This makes them the preferred choice when the conveying route is complex.

Some other tube conveyors can only have one single outlet or, in order to have more, the design required is complex and costly.

Tubular Drag Chain Conveyors can be configured to have as many inlets or outlets as required.

Mobile units

Smaller mobile units can also be used for loading, unloading and packing applications.

One of the benefits of these tubular drag conveyors is that they can start up fully loaded.

There is no need to empty the conveyor after a shut-down unless your material will harden or change its characteristics over time.

Highly energy efficient

They are highly energy efficient when compared to pneumatic conveyors as they typically use a single low power motor and do not need rotary valves or other accessories. Little maintenance is required which therefore means low cost of ownership.

There are 3 main layout options, Horizontal Flat, Horizontal Upright, and Vertical. See our layout options page.

Contact Renby: +44 (0)1829 740913 or e-mail to discuss your requirements

A Schrage tubular drag chain conveyor.